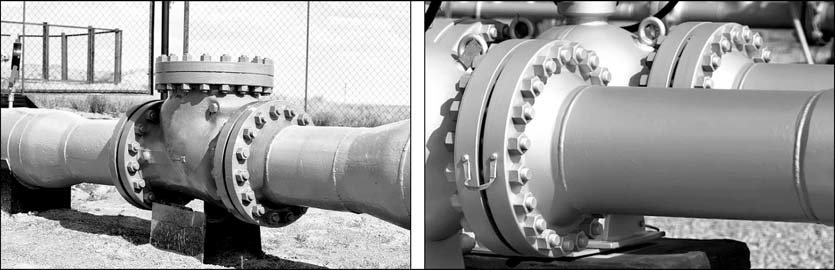

Flanges

Star Pipes and Steel Supplies FZCO, Each type of flange and standard ensures compatibility and reliability across a variety of applications, from low-pressure water pipelines to high-pressure oil and gas systems. The choice of flange type depends on factors such as the system’s pressure, temperature, and the materials being transported.

Flanges are critical components used in piping systems to connect pipes, valves, pumps, and other equipment to form a complete system. They provide easy access for inspection, cleaning, and modification of the piping network. Here’s an expanded look at the types of flanges and the international standards they are manufactured to:

International Specifications:

Flanges manufactured to ANSI standards are widely used in North America and other parts of the world.

These flanges are categorized by pressure class and designed to meet specific dimensional and material requirements for various applications.

DIN flanges are standardized by the German Institute for Standardization and are commonly used in Europe and other regions.

These flanges adhere to metric sizing and are used in a range of industries including chemical, petrochemical, and manufacturing.

These standards ensure that the flanges meet the stringent requirements of the petroleum industry, focusing on safety, quality, and performance.

API standards are designed specifically for the oil and gas industry, particularly for high-pressure, high-temperature applications.

API flanges are typically used in oil exploration, refining, and production operations.

These standards ensure that the flanges meet the stringent requirements of the petroleum industry, focusing on safety, quality, and performance.

Types of Flanges:

-

These flanges slide over the pipe and are typically welded both on the inside and outside to provide strength and prevent leakage.

-

They are easy to install and align, making them ideal for low-pressure, low-temperature applications.

-

Common in applications where space is tight and ease of installation is a priority.

-

Used to close off or seal the end of a piping system or pressure vessel, without any opening for fluid flow.

-

Typically installed when future expansion of the piping network is anticipated or where temporary closure is needed.

-

Designed to withstand high pressure and temperature in piping systems.

-

Characterized by a long tapered hub that is butt-welded to the pipe.

-

Designed for high-pressure applications and environments where repeated bending and stress are expected.

-

Provides a smooth transition from the flange to the pipe, reducing stress concentration.

-

Used primarily in critical applications like oil, gas, and petrochemical industries.

-

These flanges have threads inside the flange bore that match the external threads on the pipe.

-

They are used in systems where welding is not possible or advisable, such as in explosive environments.

-

Ideal for low-pressure applications where the pipe materials may be unsuitable for welding.